Amidst the competitive environment of construction and decorative material, PVC foam boards are distinguished by their versatility, light weight and resistance. I also understand that the market requirements are changing - clients require now a product that has a high level of surface finish and a strong and sophisticated interior that has a solid cost benefit without compromising its structural integrity. This is where we feel that co-extrusion technology does seem to change the game and in Jiangsu Xinhe Intelligent Equipment Co., Ltd., we have refined its usage in high-performance PVC foam board production lines.

What is Co-extrusion and Why Does It Matter?

I define co-extrusion as a highly developed manufacturing method by which two or more disparate materials, or material type recipes, can be concurrently extruded into one die, and they are bonded together to create a multi-layered product.

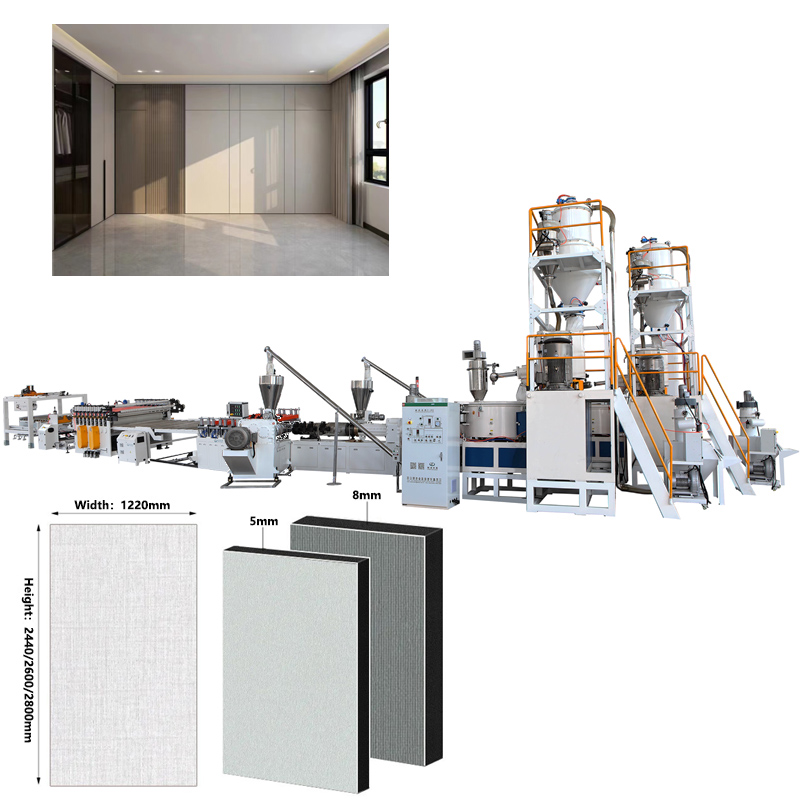

When we use the process on PVC foam boards we normally have a high quality of a thin outer layer that comes out to be smooth, scratch resistance as well as highly printable, and has a lightweight, foamed PVC core that gives it strength, insulation and it also saves a large portion of material. What we are stressing here is by no means a mere lamination, but a fusion on a molecular level, attained during the extrusion process of a board in the form of a monolithic where the layer properties are well clearly defined.

Xinhe’s Co-extrusion Advantage: Engineering for Excellence

We are aware that the processes needed to introduce co-extrusive into a production line need exact engineering and profound understanding of the process. In Xinhe, we provide an optimally harmonized platform that aims at stability, efficiency, and high output that provide reliable quality performances in harsh industries.

The Heart of the System: Dedicated Extruders & Precision Die Design

We are based on synchronized twin-screw extruders in our co-extrusion lines. We are committed to one extruder to work on the exact compound needed in order to create the dense and glossy surface layer and we are also committed to another extruder to do the foamed core formulation, so that the melt is equally homogeneous and temperature is perfectly controlled over each stream of material. One of the fundamentals of innovation that I would identify is our co-extrusion die that is specially designed. Xinhe engineers have designed dies which accurately introduce and bring together the two melt streams to allow a defect free and uniform interface between layers without an undesirable blend. This enables us to ensure a clean cut defined layer structure and clean, flawless surface finish throughout the board thickness.

Unmatched Benefits for Manufacturers and End-Users

Making use of the co-extrusion technology of Xinhe, the manufacturers can access a new level of value in their products and operations:

Enhanced Product Performance: React with a hardness and quality comparable to solid sheets and a surface that is lightweight, easy-workable and has the thermal/acoustic insulation properties of a foamed core.

Significant Material Cost Reduction: The foamed core may take up to 70-80% of the volume of the board and this means significant savings on the use of virgin PVC compound which is more expensive but has no negative impact on structural performance.

Superior Surface Variety: The small surface is perfect to print, laminate or paint direct or as a surface, and nowhere is it easier to apply high end decorative solutions, including both signage and furniture, as well as interior wall covering.

Improved Production Efficiency: The lines are designed to achieve consistent, fast production without wastage and downtimes that multi-steps lamination products.

Total Solution Integration: From Feeding to Haul-Off

A co-extrusion line does not consist of merely extruders and a die. Xinhe offers delivery of a complete and turnkey system:

Proportional dosing systems to facilitate correct and constant feeding of raw materials and foaming agents.

Advanced multi-stage calibration and cooling units which guarantee accurate board thickness, excellent surface reproduction, and regulated foam cell structure.

Precision haul-off and cutting equipment haul-off and cutting equipment.

Conclusion: Lead the Market with Advanced Co-extrusion

We observe that the use of co-extrusion technology is not a niche benefit anymore, but a level or a newly developed standard of high-value competitive PVC foam boards. It enables us to assist the manufacturers to develop high quality products at optimal cost-structures and with the quality being constant.

At Jiangsu Xinhe, we take our patented extrusion technology and rich application experience to provide to the market lines of production, not machines, but strategic instruments of market leadership. We have the durability of our co-extrusion designs, which will allow our customers worldwide to develop their product lines and earn the market share.

Do you have the readiness to modernize your production of PVC foam boards and test the capabilities of using co-extrusion technology? Jiangsu Xinhe Intelligent Equipment Co., Ltd. is asking you to reach out to us today, so as to implement a tailor-made solution that will propel your development.

Table of Contents

- What is Co-extrusion and Why Does It Matter?

- Xinhe’s Co-extrusion Advantage: Engineering for Excellence

- The Heart of the System: Dedicated Extruders & Precision Die Design

- Unmatched Benefits for Manufacturers and End-Users

- Total Solution Integration: From Feeding to Haul-Off

- Conclusion: Lead the Market with Advanced Co-extrusion

EN

EN

AR

AR

BG

BG

HR

HR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SL

SL

UK

UK

VI

VI

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MK

MK

HY

HY

AZ

AZ

UR

UR

BN

BN

LA

LA

NE

NE

MY

MY

KK

KK

UZ

UZ